Goals and ambitions

An important goal of the quality management at Fresenius Kabi is to monitor the applicability, efficacy, and safety of products and services, as well as the success of therapies, and their continuous improvement. To ensure this, the company has established an integrated quality management system, a monitoring and reporting system, and product risk management.

Goals of Fresenius Kabi

Download(XLS, 35 KB)| Timeframe | Status | Further information | |

|---|---|---|---|

| Benefit-risk ratio surveillance of our products: Compliance rates of 100% based on quality-related reporting: | Ongoing | Goals for 2023 partially achieved | Guidelines and regulations |

| Individual Case Safety Reports | |||

| Reporting of periodic safety reports | |||

| Transmission of vigilance data |

Organization and responsibilities

Since December 2023, the central function Quality Management reports directly to the member of the extended leadership team of Fresenius Kabi (Executive Leadership Team – ELT), which is responsible for the function Technical Operations & Quality. This function defines overarching standards and requirements for the business segment’s quality management. Further quality assurance functions are defined throughout the business segment to ensure adherence and compliance with the business-segment-wide standards and requirements.

Guidelines and regulations

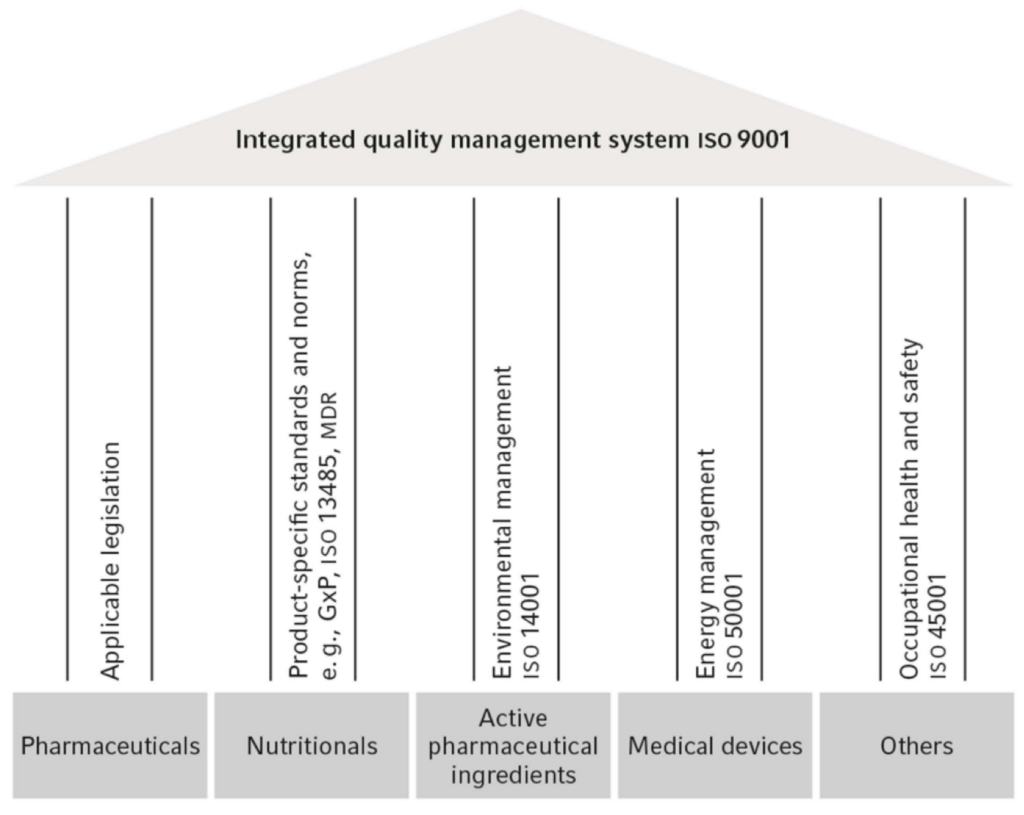

Fresenius Kabi’s quality management system is organized in accordance with the ISO 9001 standard and is binding for all organizations of the business segment. Compliance with the standard is reviewed by TÜV SÜD in annual audits at a global level and covers 123 Fresenius Kabi organizations through a matrix certification; one further organization holds a local ISO 9001 certificate. In addition, numerous manufacturing plants have supplementary certifications, such as ISO 13485 for medical devices, a food safety management system according to ISO 22000, or Good Manufacturing Practice (GMP) in general for pharmaceuticals.

Quality standards Fresenius Kabi

Download(XLS, 35 KB)| Quality standard | ISO 9001 | ISO 13485 | GMP / cGMP |

|---|---|---|---|

| Number of certified entities | 124 | 26 | 46 |

| Number of certified entities, in %1 | 98 | 100 | 100 |

| 1 Coverage target 100% of relevant entities, variation due to organizational changes, e. g., opening, closing of locations; % coverage subject based on entities for which the standard is of relevance. | |||

Fresenius Kabi regularly conducts internal quality audits to ensure the effectiveness of the quality management system and compliance with internal and external standards and requirements. Suppliers are subject to a qualification process based on the relevance of the delivered material or service. Also, the supplier’s qualification and their recertification are audited every three to five years. Inspections by regulatory authorities and audits by independent organizations are performed along the value chain at Fresenius Kabi. Fresenius Kabi promptly takes steps to deal with any weaknesses or deficiencies discovered during inspections.

Integrated quality management fresenius kabi

In 2023, Fresenius Kabi performed 58 internal audits. The external audits and inspections in the reporting year amounted to 111 (2022: 87), of which 22 were regarding GMP by the U.S. Food and Drug Administration (FDA), the Australian Therapeutic Goods Administration (TGA), Health Canada, and European pharmaceutical authorities, and 15 were regarding the Quality Management System audits from TÜV SÜD (notified body for ISO 9001).

Based on the respective deviations, an audit and inspection score is calculated by Fresenius Kabi. The score is calculated by addition of the number of critical and major observations identified during GMP inspections by the authorities mentioned above and the number of non-conformities identified during TÜV SÜD ISO 9001 audits, divided by the overall number of these inspections and audits. Critical observations or deviations, if any, or certification status withdrawal are weighted with a defined multiplier. The score shows the average number of major deviations identified during the inspections and audits considered.

Audits and inspections

Download(XLS, 46 KB)| 2023 | 2022 | 2021 | |

|---|---|---|---|

| Audit and inspection score1 | 1.92 | 2.3 | 1.9 |

| Internal audits | 58 | 45 | 58 |

| External audits and inspections | 111 | 87 | 94 |

The audit and inspection score1 was 1.92 in 2023 (2022: 2.3). Observations have been and will continue to be addressed by corrective and preventive actions (CAPAs) and effectiveness checks have been and will continue to be defined. The observations neither impacted the GMP certification nor the ISO 9001 certificate.

In 2023, no events with a material adverse impact were recorded that conflict with our aforementioned quality management goals.

1 The calculation of the audit and inspection indicator takes into account all audits and inspections carried out in the reporting year for which information on deviations is available by the end of January of the following year.

2 The key performance indicator as part of the short-term variable remuneration (STI) of the Management Board is audited with reasonable assurance, as explained in the independent practitioner´s report starting on page 201 of the Group Non-financial Report.

Monitoring and reporting systems

The monitoring of adverse reactions or events (side effects) associated with the use of medicinal products is referred to as pharmacovigilance (drug safety). The statutory pharmacovigilance commitments relate to our medicinal products for human use. Similar regulations exist for medical devices. Fresenius Kabi has established various standard operating procedures for the continuous monitoring of the benefit-risk ratio of its products and assesses their successful implementation based on specific indicators. The companies vigilance activities are designed to ensure the safety of its products: in this way, the company can identify any changes in the benefit-risk ratio of its products at an early stage and react in a timely manner. Fresenius Kabi’s Corporate Safety Officers are responsible for the global vigilance system. These functions help to ensure that the company can respond quickly to safety-relevant events. Fresenius Kabi promptly informs its customers and the public about matters or measures concerning product and patient safety; this may be done directly or through appropriate public channels, if applicable.

These early-warning systems are designed in such a way that trained complaints and safety officers worldwide record complaints and side effects in IT systems and forward the respective information to experts for review.

Fresenius Kabi collects and assesses reports about individual side effects and reports them to health authorities worldwide in accordance with regulatory requirements. The business segment aims to submit all safety reports in accordance with the applicable regulations and therefore strives to report 100% of the Individual Case Safety Reports (ICSRs) to the authorities in time.

In addition, Fresenius Kabi regularly evaluates the benefit-risk ratio of its products based on safety-related information from various sources (e. g., adverse event reports, medical literature). The results of these analyses are submitted to authorities as periodic safety reports. Fresenius Kabi aims to submit all periodic safety reports worldwide to authorities in due time. In 2023, the benefit-risk ratio of all pharmaceutical products remained unchanged.

According to regulatory requirements, Fresenius Kabi, as a pharmaceutical company, is obliged to describe its vigilance system in a Pharmacovigilance System Master File (PSMF). Fresenius Kabi uses a global database to collect and evaluate vigilance data on a quarterly basis from all local marketing and sales units for the PSMF. The goal is to receive timely data from all marketing and sales units worldwide.

Compliance rates quality

Download(XLS, 35 KB)| in % | 2023 | 2022 |

|---|---|---|

| Side effects: Individual Case Safety Reports reported in time (globally) | 99.9 | 99.3 |

| Benefit-risk ratio: in-time transmission of periodic safety reports (globally) | 99.1 | 100 |

| Internal in time transmission of vigilance data | 100 | 100 |

In addition to the timely evaluation and reporting of single side effects to authorities, cumulative evaluations on side effects are carried out to guarantee the safety of the products (signal detectionSignal detectionVarious activities used to determine whether new risks exist in connection with an active ingredient or pharmaceutical product, or whether risks known to us have changed. A review is based on our safety reports, aggregated data from the pharmacovigilance systems, and studies and information from the scientific literature or other data sources available to us. Signal management also includes the assessment of new evidence and related recommendations, decisions, communications, and follow up on the information.). These include important events, e. g., reports about side effects with a fatal outcome, to evaluate if new information is available about a known side effect profile or a new side effect of a product leading to a changed benefit-risk profile. No such information became known for the business segment’s products in the reporting year.

In the reporting year 2023, Fresenius Kabi accomplished very good compliance ratios for the quality-related reporting. In cases where targets were not achieved, measures were internally initiated to ensure that a timely submission of reports will be conducted in future.

Product risk management

Globally responsible safety officers react promptly when Fresenius Kabi becomes aware of potential quality-related issues. They initiate and coordinate necessary actions worldwide, such as product recalls. With its early-warning system, Fresenius Kabi evaluates any quality-related information from various risk areas to identify risks early and take corrective and preventive actions. Information is obtained from databases for complaints and side effects, internal and external audits, and from key performance indicators used for internal control and optimization of quality processes. With these systems, Fresenius Kabi evaluates the safety profile of its products at a global level.

We ensure through internal procedures that we can react promptly and adequately, if new adverse drug reactions are identified for one of Fresenius Kabi’s products. These new side effects are communicated to healthcare professionals via a specified format called a Dear Health Care Professional Letter in a timely manner. We thus help to ensure that patients are treated with products that meet our safety standards. In the reporting year, the benefit-risk ratio of no product changed due to new side effects.

Communication of new side effects

Download(XLS, 35 KB)| 2023 | 2022 | |

|---|---|---|

| Number of communications to healthcare professionals regarding new adverse reactions to a product | 1 | 1 |

Labeling and product information

Fresenius Kabi’s products are classified, e. g., as pharmaceuticals, nutritional products, active pharmaceutical ingredients, or medical devices, based on global or national regulations and standards. The marketing of these products is subject to various laws and regulations to ensure complete and fact-based product information. Fresenius Kabi has a global policy and global standard operating procedures for its product information to ensure that it is in accordance with applicable laws and regulations and that the product information for correct use is clear, accurate, and not misleading.

The products of Fresenius Kabi are also subject to certain labeling requirements. The labeling of the products is checked regularly as part of the regulations and vigilance activities – e. g., compliance with laws relating to side effects of medicinal products – and updated if necessary. For example, product labeling is updated if competent authorities, e. g., the Pharmacovigilance Risk Assessment Committee (PRAC) of the European Medicines Agency (EMA), publish relevant information. The dedicated function at Fresenius Kabi uses an electronic management system for product labeling to manage the information necessary for labeling or printed packaging material and to ensure its correctness. The requirements of the European Falsified Medicines Directive or the U.S. Drug Supply Chain Security Act (DSCSA) lead the way in this context. Fresenius Kabi takes into account their specifications and has introduced appropriate processes for serializationSerializationLabeling of a pharmaceutical package with a unique serial number that is combined with the item number (GTIN), batch number, and expiration date. This combination is encoded in a 2D Data Matrix code, which is used to verify the authenticity of the medicine when it is dispensed., testing, and traceability for the relevant products. Further information on transparency in healthcare can be found in the Strategy and management chapter.

Contact

Fresenius SE & Co. KGaA

Group ESG

sustainability@fresenius.com