For decades, water consumption has been increasing worldwide and water shortages are occurring in more and more regions. We too need water both at our production plants and in our health care facilities. We therefore handle this scarce and vital resource responsibly. We work with management systems and control systems globally to ensure that water quality meets internal and external regulatory requirements so it can be used safely during production, in processes, and in our health care facilities. The health of our patients and employees must be protected. The aim of our water management is therefore not only to ensure the highest quality and sufficient availability of freshwater but also to avoid unnecessary polluting the sources from which we obtain water or into which we discharge our wastewater. Water withdrawal for the Fresenius Group has been surveyed annually since 2016 as a part of non-financial reporting.

Our approach

Fresenius continuously reviews national and international regulations on water management. This ensures that internal principles, guidelines, and standard operating procedures are always up to date or often go beyond regulatory requirements, e. g., within the framework of global management handbooks. Depending on the operating activity, either environmental or hygiene experts ensure that internal guidelines and external regulations are adhered to.

At our clinics and hospitals, most of the water withdrawal is from municipal water supplies. We have implemented applicable risk management procedures that come into action if impurities are detected or if the quality of water is not compliant with standards set. Further, dedicated reporting lines provide transparency within the business segments. The local government is informed of any detected critical deviations from local drinking water provisions.

In Germany, some of our clinics are designated as testing centers for local drinking water quality. In this way, we support not only the safety of our patients, but also that of the surrounding population and the municipalities that supply us with drinking water.

In production, water is needed for sterilization and cooling processes, as a component in the production of medical products, for hygiene procedures, and as a vital element of our dialysisDialysisForm of renal replacement therapy where a semipermeable membrane – in peritoneal dialysis the peritoneum of the patient, in hemo dialysis the membrane of the dialyzer – is used to clean a patient’s blood. solutions. 70% of water withdrawal in production is sourced from the municipal water supply, 26% through groundwater sources, and 4% from surface water. Fresenius operates in highly regulated markets with regard to hygiene, sterility, and product quality. This ranges from standard operating procedures for risk prevention and maintenance to monitoring strategies, as well as emergency and response management systems with regard to environmental incidents.

Fresenius Medical Care

Large volumes of water are required both in production sites and in dialysis clinics – dialysis requires a significant quantity. It is critical that the water Fresenius Medical Care uses for dialysis is of high quality, which is why the company generally uses municipal water that is treated further in its dialysis clinics.

Progress and measures in 2021

In 2020, Fresenius Medical Care assessed water stress at production sites. This determined that 7% of sites are in areas defined as locations with an extremely high risk of water stress. Water stress is a situation when the demand for water surpasses the available amount during a certain time, or when poor quality restricts its use. In 2021, the business segment followed up on the results of this assessment in various ways. For instance, it conducted interviews with teams at selected sites in areas with an extremely high risk of water stress to raise awareness of the issue and to assess the need for potential remedial measures. The company expanded the scope of its water stress assessment to include the majority of its dialysis clinics. Fresenius Medical Care used the World Resource Institute’s Aqueduct tool to collect the data. According to the results, 12% of included dialysis clinics are in areas defined as locations with an extremely high risk of water stress. Additionally, Fresenius Medical Care has started to analyze water stress scenarios for 2030 and 2040. The company aims to complete the assessment by the end of 2022, and plans to integrate the findings into its risk management.

To generate water savings at its production sites, Fresenius Medical Care initiated several projects in 2021. For example, in the United States, the business segment optimized the maintenance cycles pre-treatment filters for the water purification system at its dialysis clinics. This allowed Fresenius Medical Care to properly maintain and operate the water equipment while reducing the system’s water consumption. As part of the Green and Lean initiative, the business segment implemented projects that aimed to, for example, save water through improvements in its internal water treatment procedures and improve processes within its water cooling and recovery system.

Fresenius Kabi

Water is primarily used in production at Fresenius Kabi, e. g., for cooling or in sanitary facilities, and is discharged as wastewater. Some manufacturing sites are reusing water, e. g., by using condensate water from installed air handling units or in steam condensate recovery systems. The business segment also uses water for its products, e. g., for infusion solutions such as sodium chloride. The water used for this purpose must meet stringent quality requirements to ensure product quality and patient safety. Fresenius Kabi’s global environmental standard operating procedures and working instructions include instructions for the responsible handling of water, including the control of wastewater. Each of Fresenius Kabi’s manufacturing sites is required to evaluate its environmental impact, e. g., from water usage and wastewater. Water management measures consider a reduction in water and wastewater volumes, and monitor the quality and authorized withdrawal of water and discharge of wastewater.

Water discharges are locally managed at the sites in accordance with applicable local regulations. Water discharge by quantity is regularly reported to global EHS in accordance with internal standards and guidelines. Fresenius Kabi is in the process of implementing the Common Antibiotic Manufacturing Framework (CAMF) of the AMR Industry Alliance. According to the CAMF requirements, wastewater contaminated with antibiotic residues should not be discharged untreated. In 2021, the business segment started to establish corresponding processes and measures at the relevant sites that produce antibiotics. These processes and measures complement the existing internal standards and procedures.

Water availability at Fresenius Kabi’s production sites is important to ensure business continuity. The business segment analyzes the water situation using the World Resources Institute’s Aqueduct Water Risk Atlas, which contains information on current and future water risks at specific locations. Fresenius Kabi has identified manufacturing sites that are in areas with extremely high or high risk of water scarcity. At these sites, efficient water management is especially important to ensure water availability for production and to prevent negative impact on the local water situation as far as possible.

Progress and measures in 2021

In 2021, the management approach and the governance structure of Fresenius Kabi remained as reported in 2020. Progress focused on the introduction of CAMF at the antibiotic-producing manufacturing plants and the evaluation of methods for treating wastewater as well as the introduction of systems to control Predicted No-Effect Concentrations (PNEC) as defined by the AMR Industry Alliance. PNEC values can be used to determine discharge concentration targets for antibiotics that are not expected to cause environmental effects.

In 2019, Fresenius Kabi established an internal information platform, the Global Competence Cluster Energy and Water Management, in which all production sites can participate. Exemplary practice and information exchange is thus globally facilitated. Furthermore, a regular newsletter featuring exemplary practices and on-going projects, a podcast, and regular virtual coffee breaks to foster exchange were implemented in 2021. The internal information platform has already produced ideas for improvements. The manufacturing plant in Port Elizabeth, South Africa, for example, concluded the implementation of three water-saving measures in 2021: the bathroom facilities were improved with water-saving faucets and shower heads, other faucets were retrofitted with water-saving aerators, and the existing urinals replaced with waterless models. These measures are in accordance with the strict hygiene and washing service provisions for our employees in production. Overall, these measures are estimated to save 885,000 liters of water annually.

Potential intracompany transfers of exemplary practices within Fresenius Kabi and new projects are currently being evaluated.

Fresenius Helios

As a hospital operator, the availability and quality of water is extremely important to Fresenius Helios, in all countries and at all sites. The focus of water management at the Helios clinics lies on ensuring an uninterrupted supply of water of consistently high quality and on preventing microbiological contamination. The use of water as a resource in health care facilities is subject to strict legal requirements both in Germany and in Spain. Rainwater, for instance, can only be used in areas that are not critical for patient safety. Compliance with the respective applicable regulatory requirements, e. g., the Drinking Water Ordinance (TrinkwV) in Germany, has top priority. In order not to endanger patients, employees, or other people at any time, water management is closely linked to hygiene management.

The company's own guidelines and specifications determine the hospital-specific procedures. Further internal requirements regarding drinking water quality apply. These must be implemented in all German and Spanish facilities. For these reasons, Helios does not reuse water or use gray water – i. e., treated water from showers or washbasins.

Helios Spain supports the careful use of water, as there is a water shortage in certain Spanish regions that exposes the country to the risk of increasing desertification.

For the discharge of wastewater, Helios Spain and Helios Germany must comply with strict regional and local legal requirements, which are monitored within the respective wastewater treatment plants. Deviations are reported directly to the hospital concerned and forwarded to all responsible departments through established reporting chains. After evaluating an incident, Fresenius Helios aims to ensure that the requirements are met in future. This is enabled through measures like technical improvements or changes to processes and additional training.

Progress and measures in 2021

In 2021, the management approach and governance structure in the water management area of Fresenius Helios remained as reported in the previous year.

Helios Spain set a target in 2021 to optimize water consumption in the clinics.

Fresenius Vamed

For Fresenius Vamed, a sufficient supply of fresh water for patient well-being and hygiene is a key element in the planning, construction, and operation of health care facilities. The health care facilities built by Fresenius Vamed use construction and sanitation technology that enables optimal water management – adapted to local regulations. At the same time, intelligent water management must under no circumstances undermine hygiene measures or jeopardize the well-being of patients. The largest freshwater users at Fresenius Vamed are rehabilitation clinics with therapy pools, e. g., in the orthopedics department, and facilities that sterilize used medical instruments.

Fresenius Vamed uses local management systems, process owners, and operating procedures to ensure that the respective local guidelines on water and wastewater are strictly adhered to. The internal principles, guidelines, and standard operating procedures are adapted to the applicable regulatory requirements.

Due to the material significance of fresh water use for compliance with hygiene measures and thus patient safety, no significant reductions in water consumption are made. In the long term, the business segment aims to achieve constant water consumption. Secondary use of water is not considered an urgent priority in view of the hygiene issues to be observed.

In contrast to industrialized countries with good infrastructure and strict regulation, adequate water supply in developing markets is a major challenge. In the non-European countries where Fresenius Vamed is active in project business, legal requirements for water quality are often not comparable with the high standards required for the operation of a health care facility in Europe, for instance. The same applies to the treatment of wastewater. Many projects require the use of freshwater and wastewater treatment plants. The non-European projects are implemented according to the guidelines for water quality of the World Health Organization (WHO). Fresenius Vamed aligns the high-quality standards for the plants to be built with the requirements set by international project financers and implements them during the planning phase.

In project business, Fresenius Vamed ensures that the latest generation of water-saving technologies is used. Future operators and employees receive comprehensive training. In the non-European markets, the business segment also uses fully biological sewage treatment plants in its project business to treat wastewater.

Progress and measures in 2021

In 2021, the management approach and governance structure in the water management area of Fresenius Vamed remained as reported in the previous year. Progress focused on the internal preparation of the process documentation in alignment with the ESG component of the variable compensation for the Fresenius Group Management Board.

Evaluation1

GRI 303/103-3, GRI 303-1, GRI 303-3

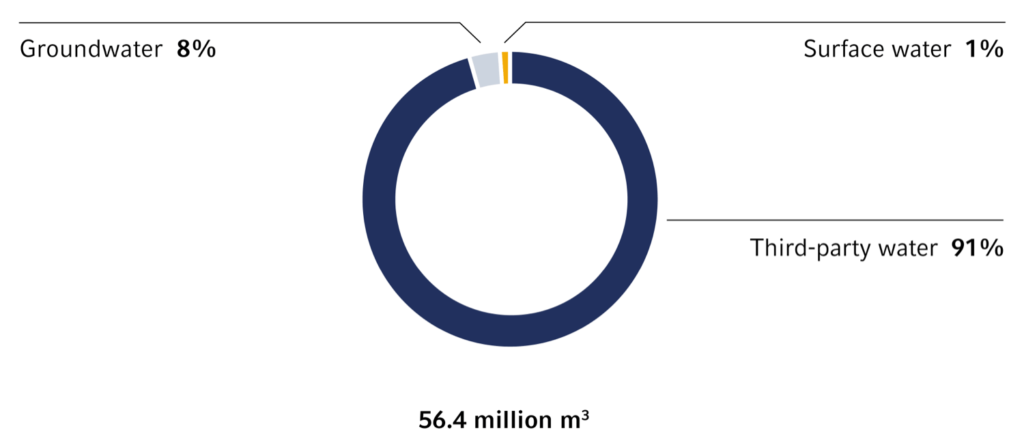

In 2021, Fresenius withdrew a total of 56.4 million m3 of water (2020: 56.2 million m3). Over the last three years, a relative reduction in water withdrawal was achieved, both in relation to sales and to FTE. Around 91% came from the municipal water supply, while about 8% was sourced from groundwater and 1% from surface water. In the hospital and rehabilitation sector in particular, water is sourced from the municipal water supply. This is due to the strict hygiene regulations and high demands on water quality in health care facilities.

Water withdrawal Fresenius Group1

Download(XLS, 35 KB)| m3 in millions | 2021 | 2020 | 2019 | 2018 | 2017 |

|---|---|---|---|---|---|

| Fresenius Medical Care | 41.4 | 41.7 | 43.2 | 42.1 | n.a. |

| Fresenius Kabi | 10.1 | 9.7 | 9.5 | 9.7 | 9.8 |

| Fresenius Helios | 4.0 | 4.1 | 3.8 | 3.7 | 3.2 |

| Fresenius Vamed | 0.8 | 0.8 | 0.7 | 0.7 | 0.3 |

| Total | 56.4 | 56.2 | 57.3 | 56.2 | n.a. |

Fresenius Group1 relative water withdrawal

Download(XLS, 35 KB)| in m3 | 2021 | 2020 | 2019 | 2018 |

|---|---|---|---|---|

| Water withdrawal / € 1 million sales | 1,502 | 1,549 | 1,612 | 1,676 |

| Water withdrawal / FTE | 201.8 | 203.1 | 218.7 | 228.2 |

Water withdrawal by source

In 2021, the reported water withdrawal at Fresenius Medical Care decreased by 1% compared with 2020. This was because mainly due to efficiency measures at various production sites and lower production volumes. The business segment is working to develop global water-related targets in addition to those it already has at regional level. It plans to define these global targets by the end of 2022.

Fresenius Kabi continued to improve its water management in 2021. Methods used to improve the treatment and discharge of antibiotic-contaminated water at the relevant sites have been identified. Appropriate measurement methods and processes will be implemented at some sites to better avoid potential negative impacts of antibiotic-contaminated wastewater. In addition, the business segment has used the results of the analysis of water-stressed areas at its production sites to align water management efficiently and sustainably to the local situation.

Water withdrawal at the business segment was 10.1 million m3 in 2021 (2020: 9.7 million m3). In 2021, several projects to reduce water withdrawal were implemented at manufacturing plants of Fresenius Kabi. Water-saving projects in 2021 included, e. g., the use of recycled water for boilers, efficient water usage in cooling towers or reduction of water consumption in restrooms. Further, the COVID-19 pandemic had an impact on water performance in some countries, due to additional cleaning activities, as well as more employees working remotely, among other factors. In addition, water performance at some sites was affected by ongoing expansion measures or regulatory validation processes, e. g., testing new production lines for quality requirements.

Fresenius Helios had not set any water management targets for 2021 to reduce water consumption specifically. Water withdrawal at the business segment was 4.0 million m3 in 2021 (2020: 4.1 million m3). Water withdrawal depends on the number of patients treated in hospitals and in 2020 and 2021 on the increased demand for sterilization and hygiene in the hospital setting.

Water withdrawal per hospital bed

Download(XLS, 35 KB)| In m3 | 2021 | 2020 | 2019 | 2018 | 2017 |

|---|---|---|---|---|---|

| Total1 | 106 | 109 | 106 | 104 | 119 |

| 1Data applies to hospital beds and water withdrawal in the business segment Fresenius Helios |

|||||

In the business segment Fresenius Vamed, water withdrawal increased slightly compared to the previous year. In 2020, the post-acute clinics were closed due to regulatory provisions to limit the impact of the COVID-19 pandemic. In 2021, only two German tourism facilities, Ostsee Resort Damp and Allgäu Resort Bad Grönenbach, were temporarily affected. The regular course of business of most facilities led to an increase in total water withdrawal.

1 Fresenius Medical Care figures include energy consumption and water withdrawal at production sites, as well as electricity consumption and water withdrawal at dialysis centers. Emissions include scope 1 and 2 emissions of production sites and Scope 2 emissions of in-center treatments in dialysis clinics. The data from Fresenius Helios encompasses as of 2018 all hospitals in Spain and the clinics in Latin America as of 2020. Fresenius Vamed’s data includes all fully consolidated health care facilities and service entities, and, as of 2018, the German post-acute care business transferred from Fresenius Helios to Fresenius Vamed. Newly acquired companies are included in the second year of consolidation, at the latest. If data of the business segments is not available in time, it is extrapolated on the basis of existing data. An adjustment will be made in the next report. Prior-year information was adjusted to conform to the current year’s presentation. Due to rounding, individual numbers and percentages presented in this report may not precisely reflect the absolute figures.